A saw is a vital piece of equipment for all kinds of woodworking and carpentry projects, but there are so many to choose from. Understanding the differences and which saws are better suited for specific tasks is critical.

Two saws that are often confused are table saws and miter saws. Both types of saw perform elementary tasks, and you can use them for some of the more common kinds of cuts.

Even so, there are some fundamental differences between them. This miter saw vs. table saw guide will help you decide which one is better for your workshop.

I’m going to be looking at some of the differences and the things you need to consider when choosing one for your workshop, as well as specific jobs each one is most appropriate for.

Table saws and miter saws are two of the most commonly used power tools, but they are not interchangeable.

Miter Saw

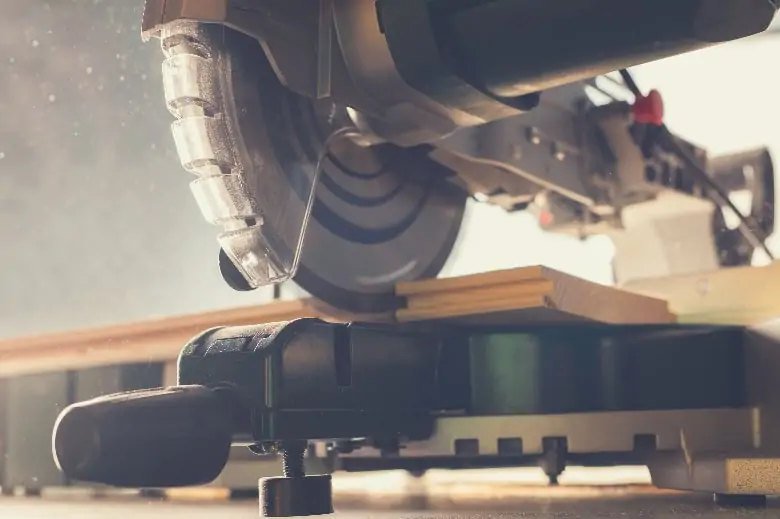

A miter saw is a power tool that has a circular blade. The blade is fixed on a moveable arm that you bring down onto your workpiece and make the cut.

The design of a miter saw means you use it for a specific purpose. You can set the swing mounted blade to different angles, and you can make angular cuts, precise crosscuts, and accurate miter cuts.

Different Types of Miter Saw

Miter saws are a very functional and useful addition to your workshop. There are three types of miter saws to choose from: standard, compound, and a sliding compound miter saw.

You can buy miter saws in a range of sizes. The most common are 12-inch and 10-inch, but you can also find 8-inch models.

Standard Miter Saw

If you want to cut wood, a standard miter saw is one of the best power tools for the job. You’ll find them in a range of power capacities and sizes. Generally, you can expect a miter saw to be light to handle, and you can use it to cut objects quickly.

Typically, you would use it for miter cuts and crosscuts, on at least a 45-degree or 90-degree angle.

Compound Miter Saw

You can use a compound miter saw to make the same cuts as a standard miter saw. However, it is much better for bevel cuts—this feature makes it a more versatile tool to have in your workshop.

There are two types of compound miter saw available: single and dual bevel models. The benefit of a dual bevel is that you can make compound cuts in both directions, and you don’t have to flip the board around when cutting.

Sliding Compound Miter Saw

A sliding compound miter saw has an additional function. You can slide the saw blade back and forwards along a track as you cut. Two types of sliding compound miter saw are available:

- Single sliding: The blade tips to one side.

- Double sliding: The blade tips to the left and the right.

You can use your sliding compound saw for making crosscuts, bevel, compound, and miter cuts.

Uses

A miter saw is typically smaller than a table saw. Therefore, the materials it can handle tend to be smaller in size. It is possible to extend the cutting surface by adding extension wings, but the dimensions of the material you can cut are still very limited. In spite of that, it is more versatile in terms of the cuts you can make.

You can use a miter saw for cutting things like door frames, picture frames, crown moldings, and window frames.

A compound miter saw, for example, can make angled cuts, cross cuts, bevel cuts, angled crosscuts, and more. Nonetheless,it is versatile enough to make a rip cut.

How it Works

You fix a miter saw to a table and bring the saw blade down onto the wood and make a cut. A sliding compound miter saw is slightly different in that you can move the saw blade across your workpiece.

Accuracy and User Friendliness

If you want to make precision miter cuts, bevel cuts of wood, or cut other soft materials such as plastic, a miter saw will perform excellently.

The position of the blade allows you to make a measured cut at a precise angle. You use the handle to adjust the angle and bevel. When you’ve found the correct setting, you push the blade through the material’s surface.

A miter saw is far more portable than a table saw: you can easily move one from place to place. If you want to enjoy stability when you move your saw, there is the option of investing in a rolling miter saw stand.

Cost

There’s not a massive amount of difference between the cost of a miter and a table saw. However, it’s worth mentioning that prices do vary from retailer to retailer.

Other types of saw come in much cheaper, for example, a circular saw. However, a miter saw is easier to use and far more flexible.

A table saw is also an alternative, but you’ll need the right accessories if you want to make the same cuts.

Pros and Cons

A considerable advantage of having a miter saw in your workshop is that it makes various types of cuts. Bevel cuts, angled cross-cuts, angled cuts, and cross-cuts are just a few examples. This saw is also adjustable, depending on your work project.

Watch this video if you want to learn more about adjusting your miter saw.

Other benefits include increased accuracy and precision. You can use a miter saw to cut 45-degree angles and it has more cutting options than a table saw. It is much better suited to smaller projects, although you can use it for large projects if you use the correct attachments.

A miter saw is very flexible in that you can use it one a table, but you can also use it on the floor. Dedicated miter saw stands are also available and will provide a stable surface, allow balanced wood placement, accommodate long pieces, and provide space for adjustable stops, fences, and rollers.

One final benefit is that a miter saw is much safer to use than a table saw.

On the downside, a miter saw is not suitable for cutting larger material, and you can’t make rip cuts with it.

Table Saw

A table saw consists of a flat table that has a saw blade built into it. The circular saw blade protrudes out from a slit in the table, and you can use it to make two types of cuts. You can make a rip cut, which is cutting a piece of wood lengthwise with the grain. A good example is if you use it to cut a 2 x 4 in half, length-wise.

It’s also possible to cut pieces of wood against the grain, width-wise. This is known as a cross-cut. A few table saws allow you to make angled cuts, but this is more the domain of a miter saw.

This type of saw is a widespread woodworking tool for both professionals and amateurs.

Different Types of Table Saw

There are several types of table saw, each with its own unique benefits and drawbacks.

Benchtop

A benchtop table saw is an excellent tool for the home DIYer. It’s not the most powerful table saw but can easily handle basic home repairs. You can also extend its functions by purchasing special blades for cutting metal and plastic.

Use a benchtop table saw for building small items of furniture such as a chair, coffee table, or dog house, arts and crafts, decorative woodworking, and minor construction projects.

Jobsite

A jobsite table saw is more powerful and rugged, and you can generally purchase one with an integrated stand. The design ensures portability, and its power increases versatility. You can use it to cut hardwoods, metals, plastics, and thick lumber.

Projects you can use it for include medium to large building and furniture, heavy-duty DIY and home improvements, professional construction, and carpentry.

Contractor

A contractor table saw includes a powerful motor, a large table, and improved torque. There are various sizes and weights, so it’s essential to choose one that suits your needs. Some are lighter than others, for example, which makes them easy to move around. That aside, a heavier one will offer more stability.

Typical uses include heavy-duty DIY and home improvement, large building or furniture projects, and professional construction and carpentry.

Hybrid

A hybrid table saw offers the best of two worlds: a contractor table saw, and a cabinet table saw. They are incredibly reliable, include a low vibration belt-driven motor, but are more affordable than a cabinet model.

You can use a hybrid model for all kinds of woodworking jobs, from the smallest to the largest, making precise cuts, large home repair jobs, and any construction work requiring an accurate and detailed cut.

Cabinet

This saw model is the king of the group. They are very popular in professional woodworking shops because they combine accuracy, power, and rip capacity exceptionally well. A cabinet saw is easy to use for making cuts and because of its design it is extremely stable.

You would typically use a cabinet saw in the construction of furniture, milling boards, large construction projects, professional-quality woodworking, and when cutting accuracy and precision are critical.

Uses

With the help of various accessories, you can use a table saw for all sorts of projects. The most common is ripping, which is cutting material to a defined width. Crosscutting, cutting material to a defined length, is another everyday use.

You can also use it for specialty cuts such as rabbet joints, compound angles, and dado cuts.

Cutting angles is an option, but you’ll need to use the miter gauge to help with the job. You can also use a jig assembly.

Watch a video that shows you how:

How it Works

The part of the saw blade that protrudes above the table is exposed to the wood. As it spins around, you push the wood into the blade, and it cuts it.

A continual cutting motion allows you to feed your workpiece into the blade in a measured, accurate, and controlled way.

The blade is fixed to a motor that’s below the table. It can be raised or lowered, depending on your needs. With the saw assembly mounted on an arbor, you can also adjust the angle.

Accuracy and User Friendliness

Table saws can make cuts that are much the same as a miter saw. However, they are not so precise. If you want to make more precise miter and crosscuts, additional accessories such as a miter gauge with extensions, a jig assembly, or a sled are necessary.

When it comes to portability, a table saw falls short. Mobile models are available, but they are still heavier and more cumbersome than a miter saw.

Cost

A table saw is not much different in price than a miter saw, but if you want to use it for something other than ripping or crosscutting, you’ll have to factor in the cost of the additional accessories.

The most obvious alternative to a table saw would be a circular saw. It is more affordable and with a guide system, you can cut perfectly straight. You’d also be able to use the same range of blades, depending on what you want to cut.

You might also consider a jigsaw, but the cut you get will be much rougher. You might also struggle to achieve a perfectly straight line.

Pros and Cons

A table saw is very versatile, powerful and excellent at making rip and crosscuts. It works very well with larger materials as well as sheet material. If you use a miter gauge, it will allow you to cut angles.

However, there are several downsides.

It is generally fixed in one place, which makes it not very maneuverable. Its size means it’ll take up a lot of room in your workshop.

You can use it to make precision cuts, much the same as a miter saw, but they will not be quite so accurate. You’ll need to have a certain amount of skill if you want to make angle cuts.

One significant disadvantage is that a table saw can be very dangerous to use. There is a considerable risk of injury, especially if you don’t follow the recommended safety measures.

If you want to know more about the different table saws, their basic parts, maintenance, and safety tips, this video is worth a few minutes of your time.

Frequently Asked Questions

Are you still feeling undecided? Let’s go over some of the most common questions.

Should I Buy a Miter Saw or a Table Saw?

The answer depends on the project you want to use it for.

For example, you might prefer a table saw if you want a reliable tool that will make easy work of large stock, can make rip cuts, and basic angles. Still, remember that a table saw is usually fixed in one position.

A miter saw, on the other hand, will be better if your workpiece is more complicated. You can move a miter saw around, and it’s cutting abilities are more versatile.

The project you’re working on also determines whether a miter saw vs. table saw is better. A table saw is better for large sheet material, whereas a miter saw suits small, intricate projects better.

Should I Buy a Table Saw or a Miter Saw First?

If you’re a newbie and looking for your first saw, you’ll find a table saw easier to grasp, although it is more dangerous. A miter saw is safer, but it’ll take longer to master.

Can I Use a Miter Saw as a Table Saw?

Using a miter saw as a table saw would be very difficult. Their design is very different. There are no restrictions around a table saw, making it better for large stock material and making rip-cuts and crosscuts.

Miter Saw Vs. Table Saw – So Which is Best For Me?

There are many factors to take into account when choosing between a miter saw vs. table saw. If you want to be able to move your saw around, a miter saw is very maneuverable. Nevertheless, a table saw is better for making rip cuts and crosscuts.

The best option will be one that addresses your needs, the size and type of projects you generally work on, and the location where you work the best.

If you enjoyed reading this guide and found it useful, please leave a comment below. Likewise, if you’ve got something you’d like to add, I’d love to hear from you.